Special Alloys

Using specialized equipment and manufacturing technologies such as VIM (Vacuum Induction Melting), ESR/VAR (Electro-Slag Remelting/Vacuum Arc Remelting), and RFM (Rapid Forging Machine),

we produce a wide range of special alloys, including nickel alloys and titanium alloys.

01

Ultra-High Strength and Corrosion Resistance at High Temperatures

Maintains excellent strength and corrosion resistance even at high temperatures, making it ideal for key industries requiring high strength and corrosion resistance, such as aerospace engine components, power generation equipment, and petrochemical facilities.

02

Diverse Product Lineup for Various Forms and Applications

We supply a wide range of products, including master alloys, wire rods, bars, flat bars, and seamless pipes, through an integrated production system encompassing steelmaking, forging, rolling, and post-processing. We also operate dedicated VIM, VAR, and ESR production lines to deliver the highest quality special alloys.

03

Korea's Largest Special Alloy Maker with the Most Extensive Distribution Network

As Korea's largest special alloy maker, we leverage the nation's most extensive distribution network to produce and deliver products in various forms and sizes to meet customer needs promptly and efficiently.

-

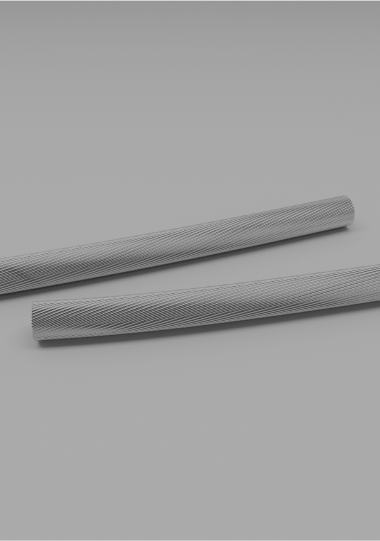

Wire Rods

5.5~34Φ

Welding solid wire

CHQ, Mesh

Fasteners

Spring

STACIR(Al Clad INVAR Wire)

-

Bars

13~250Φ

260Φ~:협의가능

Fasteners

Turbine / Engine Parts

Valves / Fittings

Disc / Shafts

Flanges

-

Flat Bars

10~200T

100~2700W

OLED Metal Mask Frame

Heat Exchanger Head Box

Turbine Blades

Clad Plate(For Welded Pipe)

-

Pipes

10~273.1Ø

1~23t

Heat Exchanger Tube

Sheath Heater

Petrochemical Pipe/Tube

FCEV sleeve

Thermocouple

-

Master Alloys

Ingot: ~30ton

Casting: 80Ø, 100Ø, 125Ø

Forging: 320~670Ø

Turbo Charger Valve

Turbine Part (Blade, Vane)

EV Burner

Capability to Produce All Other Steel Grades

-

ALLOY

625/600/601Welding Solid Wire, CHQ, Mesh

-

ALLOY

718/X750Welding Solid Wire, Spring, Mesh

-

ALLOY

825/800HWelding Solid Wire, Washer, CHQ

-

ALLOY

C276/C22/C4Welding Solid Wire

-

ALLOY

36/42STACIR(Al Clad Invar Wire)

-

ALLOY

200/201Electronic Components

-

ALLOY

400Mesh, Spring

-

ALLOY

A286(Gr.660)Fastener, CHQ

-

ALLOY

718/750/706Stud Bolts, Turbine Parts

-

ALLOY

625/617/690/600Petrochem-Parts, Turbine Blades

-

ALLOY

825/800H/367Perochem-Parts, Bolts, Valves

-

ALLOY

80AGas Turbine Parts, Exhaust Valves

-

ALLOY

C276/C22/C4Stud Bolts, Turbine Parts

-

ALLOY

901Gas Turbine Shafts, Disc

-

ALLOY

925/904LPetrochem-Valves, Stud Bolts

-

ALLOY

K500/400Pump Shafts, Fitting, Valves

-

ALLOY

A286(Gr.660)Stud Bolts, Turbine Parts

-

ALLOY

36/42OLED Metal Mask Frame

-

ALLOY

825/800HHeat Exchanger Head Box

-

ALLOY

718/X750/690Oil & Gas/Power Plant

-

ALLOY

400/K500Petrochemical/Oil & Gas

-

ALLOY

200/201/600/601Petrochemical/Oil & Gas

-

ALLOY

825/800H/904LHeat Exchanger/Oil & Gas

-

ALLOY

718/X750/690Oil & Gas/Power Plant

-

ALLOY

400/K500Petrochemical/Oil & Gas

-

ALLOY

713/713LCCasting(Turbo Charger Valve)

-

ALLOY

XCasting(Turbine Blade, EV Burner)

-

ALLOY

738LCCasting(Turbine Part, 3rd Vane)

-

ALLOY

939WCasting(Turbine Part, 3rd Vane)

-

ALLOY

625/617/718Forging

-

ALLOY

825/800Forging

-

ALLOY

C276/C22/C4Forging

Packing Specifications

Bare Packing

Securing the product with an iron frame

Hessian Packing

Packing the product externally with PP (polypropylene)

Bare Packing

Secured at 5 points with flat iron bands

Hessian Packing

1. Secured at 5 points with flat iron bands

2. Packaged with vinyl + hessian

Wooden Slate

1. Secured at 5 points with flat iron bands

2. Packaged with vinyl + hessian

3. Reinforced with wooden slates

Wooden Box

1. Secured at 5 points with flat iron bands

2. Packaged with vinyl + hessian

3. Reinforced with wooden slates