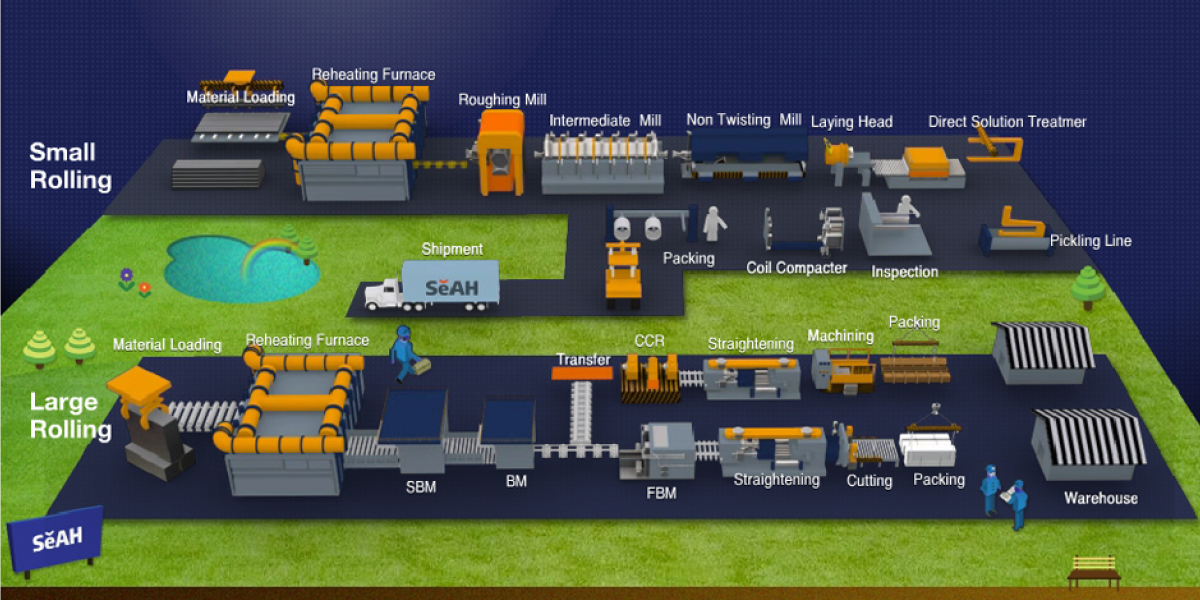

Rolling-Processing Process

Small Rolling Process

Meterial Loading

Reheating

Roughing Mill

Intermediate Mill

Non-Twisting Mill

Direct Solution Treatment

Pickling Line

Testing

Coil Compactor

Packing

Shipment

SeAH Changwon Integrated Special Steel produces wire rods and round bars with outstanding quality through the continuous rolling process consisting of the roughing mill, intermediate mill, and finishing mill. The 3-roll based kocks mill ensures consistent surface and core rolling.

The cutting-edge RSM(reducing and sizing mill) enables homogeneous micro structures and less-than-0.1mm accurate dimension control via high-speed precision rolling.

Our cutting-edge DST(direct solution treatment) technique ensures consistent control of grain size and strength.

The nitric acid-free acid pickling process, a state-of-the-art eco-friendly pickling technique, allows us to produce stainless steel wire rods with top surface quality.

Large Rolling Process

Meterial Loading Reheating Furnace SBM(Slab & Blooming Mill)

BM(Blooming Mill)

Transfer CCR(Compact Type Cassette Mill) Straightening Machining Warehouse Packing

FBM(Flat Block Mill) Straightening Cutting Packing Warehouse

Flat bars and round bars are manufactured via forging and blooming or large section rolling processes.

The newest SBM block mill is able to produce large section rolling bars and wide range flat bars.

HV-Mill allows the production of flat bars and round bars of precise dimension, based on our horizontal-vertical continuous rolling techniques.