Seamless Pipes & Tubes

Seamless Pipes & Tubes

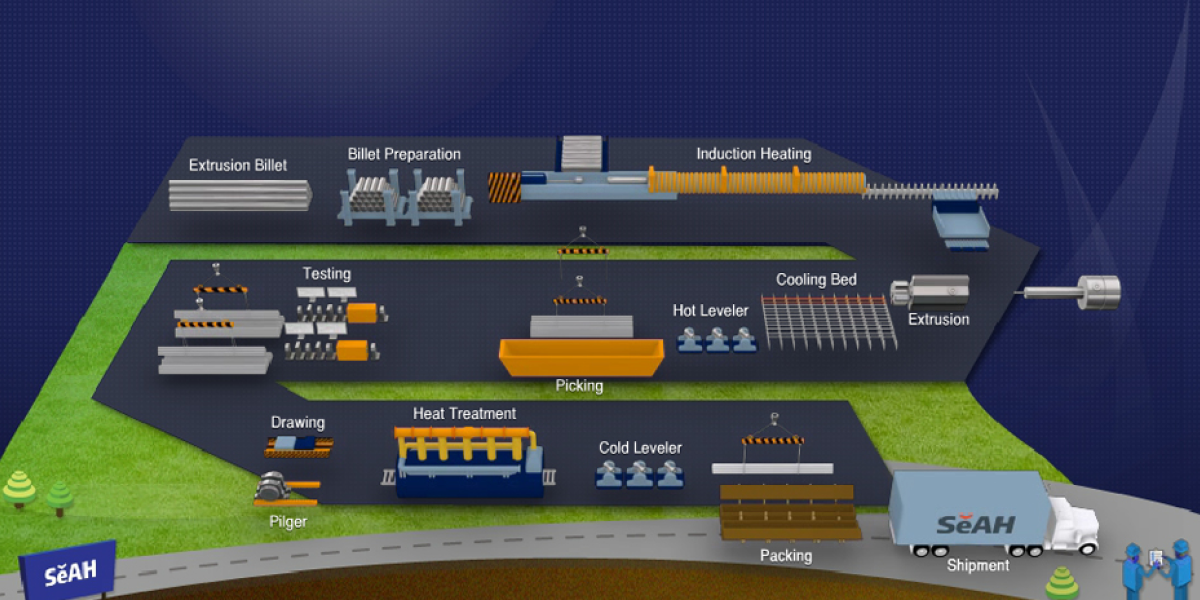

Extrusion Billet Billet Preparation Induction Heating Extrusion Cooling Bed Hot Straightening Pickling

Testing

Pilger Heat Treatment Cold Straightening Packing Shipment

Drawing Heat Treatment Cold Straightening Packing Shipment

The manufacturing of seamless tubes and pipes is started by cutting peeled round bars in the band sawing machine into designed lengths based on product size. After then, bars are moved to the boring machine to make a center hole for extrusion. After boring, the bars are heated in the induction heater, and extruded by a 2000 ton press into designed sizes of tubes and pipes.

Extruded tubes and pipes are heat treated, straightened and pickled to become hot finished products, while additional pilgering or heat treating and pickling is added to produce excellent cold finished products with high size precision.

Every piece of product is inspected by an in-line nondestructive testing machine to ensure the internal and surface quality, and provided to customers as products with perfect quality.